Strong and Lightweight |

|---|

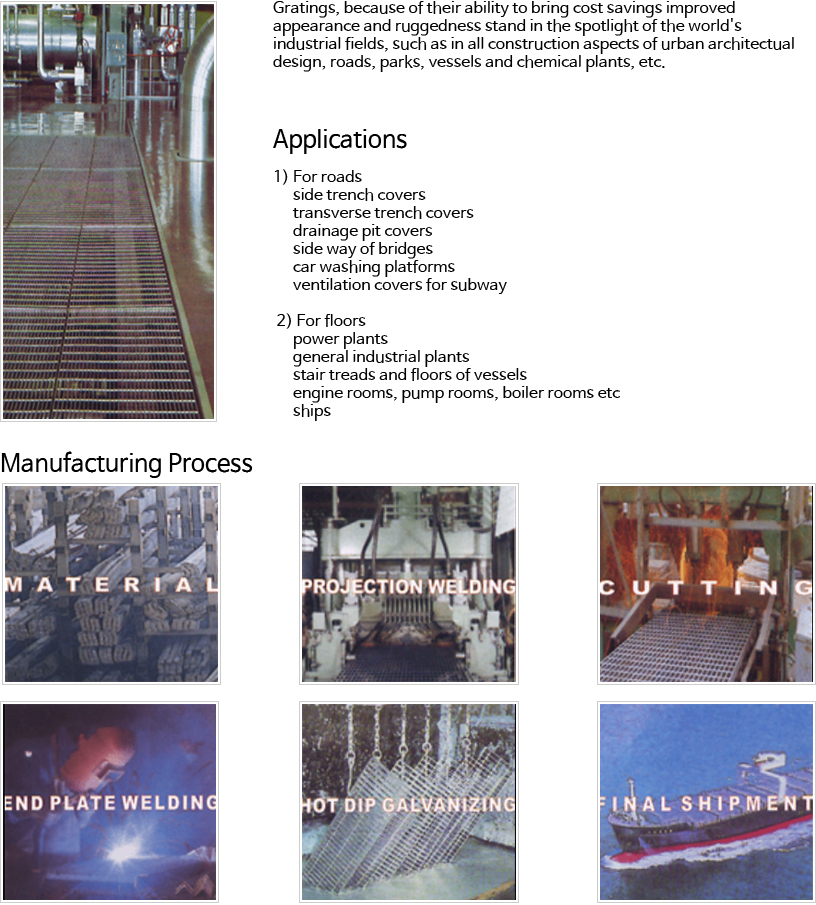

The bearing bars and cross bars are most effectively aranged together with into a grating, which possesses a high degree of strength. They are securely joined at their intersections with a specially designed projection welder, and thus grating panels become light but strong in construction. |

Super in Ventilation and Natural IIIumination |

|---|

Thegrating has a good percentage of open area, and thus is suitable for use in place, requiring ventilation and natural illumination. This makes the environment brught and clean. |

Very Economical |

|---|

A choice of grating types is available according to the use and load conditions. The grating is also zinc-coated by the hot-dip process or painted to fit the atmospheric conditions, resulting in an enhanced durability and greater economy. |

Simple Field Installation Work |

|---|

Our installation method is extremely suitable for field because the grating is easily cut according to any re-quired specifications, which makes the field work quick and easy. |

Excellent Quality |

|---|

Made of the ordinary structural rolled steel conforming to korea industrial standards, the grating is in in-tegrated production under stringent quality control at the plant equipped with sophisticated facilities. Thus, it's excellent quality is constantly guaranteed. |

Beauty in Appearance |

|---|

Geometric lattice patterns formed by the bearing and cross bars make it beautiful in appearance par-ticularly when installed. |

Safety Resulting from Non-slip Protection |

|---|

The bearing and cross bars are orthogonally arrayed in the form of a grate, affording non-slip protection in every direction to give complets safety. |

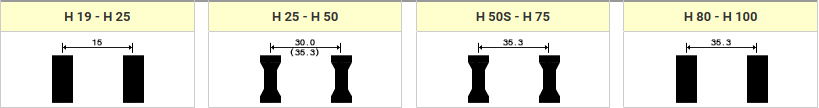

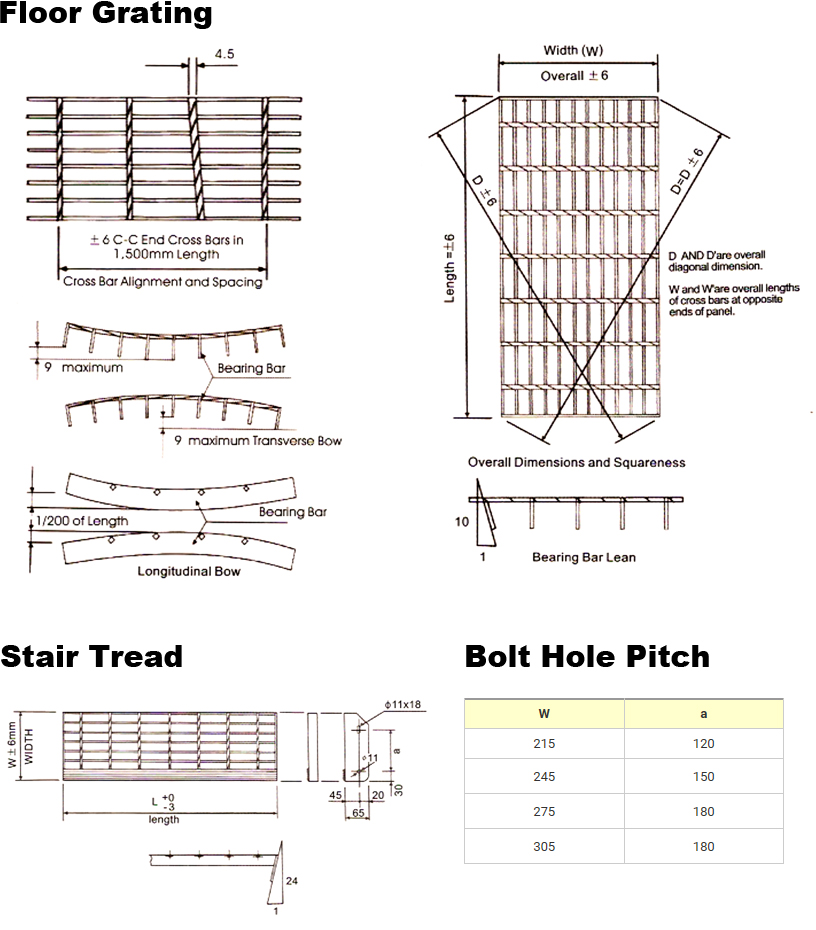

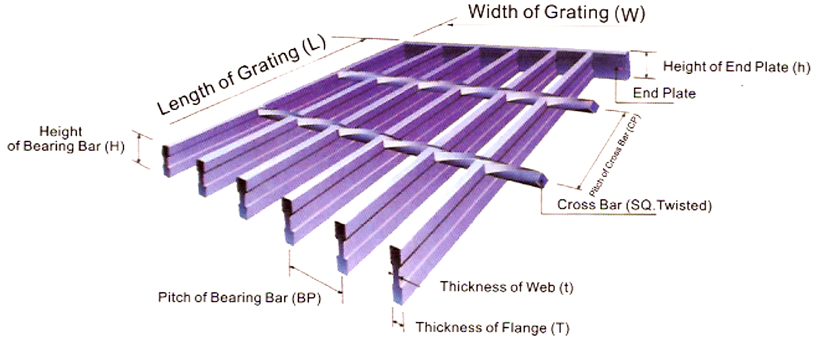

Bearing Bars |

|---|

The bearing bars are arranged perpendicular, equally spaced and parallel to one another to carry greater load. |

Cross Bars |

|---|

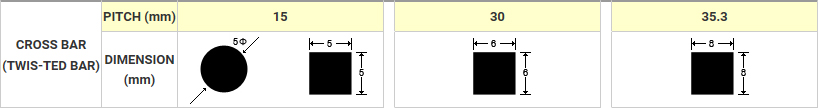

The cross bars are electroforged perpendicular and equally spaced to the bearing bars. Twisted square bars are used for cross bars to maintain the structural precision and perform a non-slip function. |

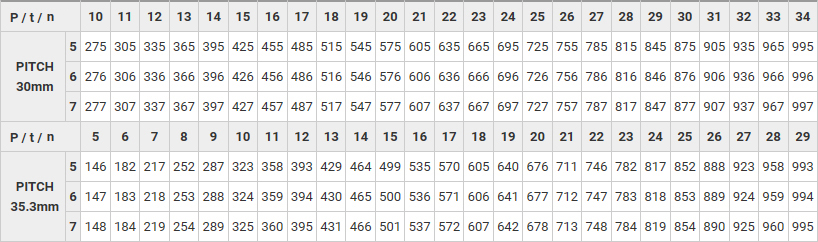

Pitch |

|---|

The center to center distance between the two contiguous bearing bars is called the bearing bar pitch and that between two adjacent cross bars is known as cross bar pitch. |

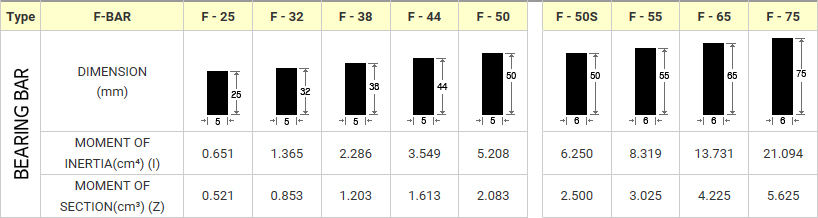

F-bar grating |

|---|

This is easy to select material for general type and also manufactured in accordance with the strict quality control with the established standard in a beautiful appearance. |

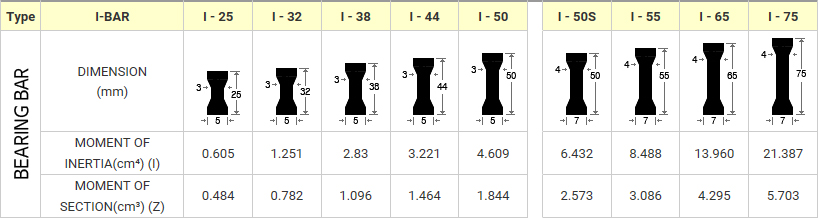

I-bar grating |

|---|

In comparison with other material of the same weight, this is very economical as well as beautiful appearance, so used widely. |

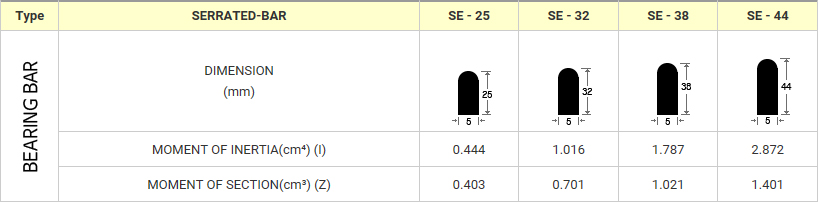

Serrated bar grating |

|---|

This is a grating panel with its bearing bars serrated on the surface to enhance the non-slip function, and ideal for use in a slippery place moistened with oils and fats or a slope. |

Grating Width and Number of Bearing Bars

I-bar type, FLAT-bar type, SERRATED-bar type

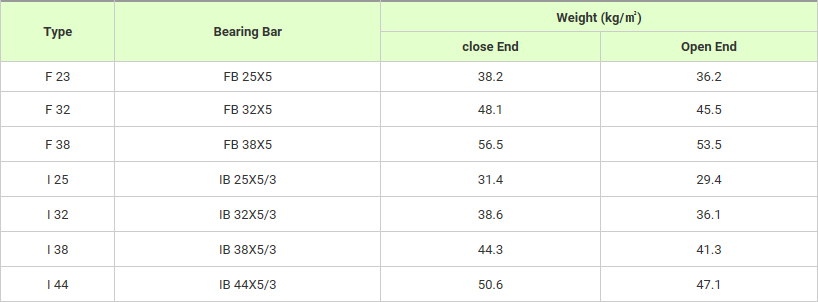

Weight of type

Bearing bar pitch